Neotek Parts

About Neotek

Neotek always puts quality first. This global leader in the production and distribution of brake drums and rotors has been supplying top-quality products to the OES and US aftermarket for over 30 years through private label programs. Efficient distribution of Neotek products is then made possible through its state-of-the-art US headquarters and warehouse facility situated in Memphis, Tennessee.

Established in 1983, Neotek ensures 99% vehicle coverage for brake rotors and drums of domestic, European, and import sedans, SUVs, and light to heavy-duty trucks. Its top-caliber brake products, award-winning customer service, Electronic Data Interchange (EDI), direct import supply chain management, outstanding category management, and customer-specific material and coating options are the key ingredients in the recipe for Neotek’s success.

Neotek looks at its customers’ business as an extension of its own. This unique philosophy is the company’s driving force in setting industry benchmarks for product quality and customer service. This industry leader implements a well-thought-out Total Customer Satisfaction system in all its processes—from product development to manufacturing, distribution, sales, and marketing. This is because Neotek’s interpretation of True Partnership is: offering responsive and comprehensive support to help customers boost their sales and make their business grow.

This industry-leading brand also invests in innovation. It takes pride in providing the industry with high-performance products and the latest developments in brake technology to help you achieve the best possible braking performance and enjoy a remarkable driving experience time and time again. As the brake steel industry evolves and the markets fluctuate, Neotek’s unwavering commitment to producing the highest-quality products and excellent customer support will not change.

Neotek Parts

All Neotek parts are made using advanced in-house processes—from start to finish—inside the company’s cutting-edge, fully vertical manufacturing facility. These brake solutions went through Neotek’s world-class foundries, accurate CNC machining centers, ultramodern finishing and coating operations, and automated packaging centers. The said company assets and capabilities solidify Neotek’s commitment to quality, innovation, modernization, and efficiency.

Neotek brake parts are recognized globally for their OE-level metallurgy and materials that deliver these time-tested, 5-point exceptional characteristics, such as:

Durability Quiet Operation Safety Comfort Rust Prevention

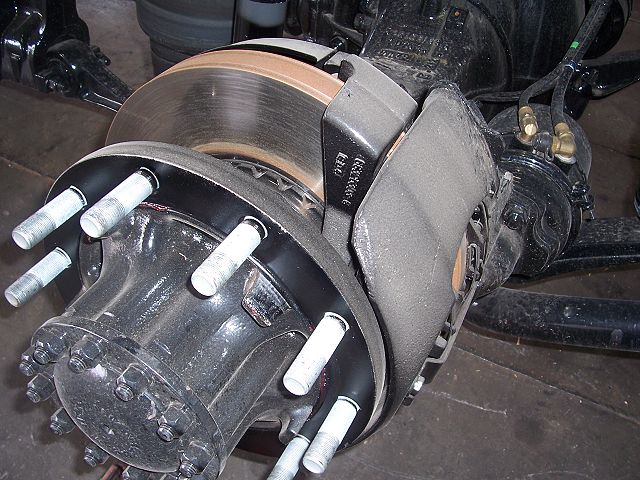

Brake Rotor

The Neotek brake rotors are crafted by engineers who have under their belt many years of experience in designing and producing products with its numerous OE and OES partners across the globe. With the brand’s dedication to manufacturing products that meet or exceed industry benchmarks, customers are assured of Neotek parts that outperform the competition.

Made from premium raw materials, Neotek brake rotors meet rigorous foundry requirements. They are provided with dry-rust preventive coating, are 100% mill balanced, and are offered installation-ready.

-

Premium Rotor

Neotek’s premium rotors are formed from high-carbon G11H18 material that provides outstanding heat transfer characteristics and sound dampening to ensure maximum performance and superb quality. They are made with high-caliber raw materials under strictly regulated operations in the company’s world-class facility. To ensure superior performance, each premium rotor part is machined to OE/OES level tolerances.

The premium rotors from Neotek are spectrometer tested to be sure that the carbon content and other elements are correct and the graphite strands are of the right size. With the right carbon content, optimal thermal conductivity can be achieved. This makes the rotor run cooler for a more dependable braking performance.

These Neotek rotors are subjected to tensile strength and hardness tests to check if they pass the required ratio for G11H18 standards. They are then CNC machined to ensure reliability and consistent quality. This brand even imposes stricter machining requirements for DTV (Disc thickness variation), run-out, mounting surface flatness, parallelism, and brake surface flatness.

Another process that makes Neotek premium rotors stand out is its CNC fine-turn finish. This procedure makes these rotors look like the OE part while cutting down surface finish roughness (Ra). These brake parts are then provided with a best-in-class coating and packaging finish, making the rotor look as great as they perform.

These Neotek premium rotors are also mill balanced to a specification that’s more than 50% tighter than industry standard rotors. The non-braking surfaces are provided with an environmentally friendly coating, and other exposed surfaces are coated with a dry rust inhibitor.

-

Standard Rotor

Neotek standard rotors are built from industry-standard G3000 SAE material. They are provided with high-quality casting, making them ready for CNC machining and strict product testing. For customer satisfaction, Neotek’s engineers adhere to industry-standard machining tolerances. A cross-directional finish is then applied to ensure a smooth surface finish and reliable brake pad seating. These standard rotors are also 100% mill balanced to reduce, if not eliminate, vibration and achieve smooth stops.

Brake Drums

The brake drums may not be among the first things that will come to mind when asked about the brakes, but they play a critical role in braking. They don’t just contribute to the safe halting of vehicles; they also maintain the vehicle’s alignment during the braking process.

Like the rotors, Neotek brake drums are also developed in-house by parts engineers that have many years of experience in creating brake products for various OE manufacturers around the world. These brake parts are provided with top-quality casting as preparation for machining through rigorous testing and process controls. CNC machining is then performed following strict industry standards to guarantee durability and outstanding quality to meet the customers’ preferences.

Additional machining or finishing is done not only to the brake shoe area but also on spots where the brake shoe backing plates may produce noise inside the drum. Neotek drums are also 100% balanced to get rid of vibration and give the vehicle smooth stops. A dry rust inhibitor is also applied for outstanding rust resistance.

Shop Neotek Products at FinditParts.com

When you want to maximize the power of your braking system, FinditParts always has your back. It is because we, here at FinditParts, believe that the best way to protect the drivers and passengers is to outfit their rig with first-rate safety solutions, particularly brake rotors and drums from the most trusted brand—Neotek. We carry a wide array of Neotek parts, so you will surely find here the items that perfectly match your application. Check out our catalog, and you will discover one of the industry’s most comprehensive inventory of parts and accessories for light to heavy-duty trucks and equipment, buses and coaches, recreational vehicles, and specialty vehicles. Are you overwhelmed by our widest product selection? Worry not. You can get the exact Neotek part you need in just a few seconds through our quick lookup feature. Give us the part number, cross reference, or keyword, and we will do the search for you. Alternatively, you can give us a ring and ask for help from our friendly and well-trained customer support staff. Let them know what you need, and they will guide you every step of the way. We also assure you that all the information and personal details you will provide us with are safe and will solely be used for your purchase. The best is, you can get the highest quality products here at prices that won’t ruin your budget. We even give bigger price markdowns during holidays and special occasions in the trucking industry, so watch out for that. FinditParts also guarantees reasonable shipping rates on all your ordered items. Shop with us now and bring your rig back on the road in no time!